High Voltage Leak Detection

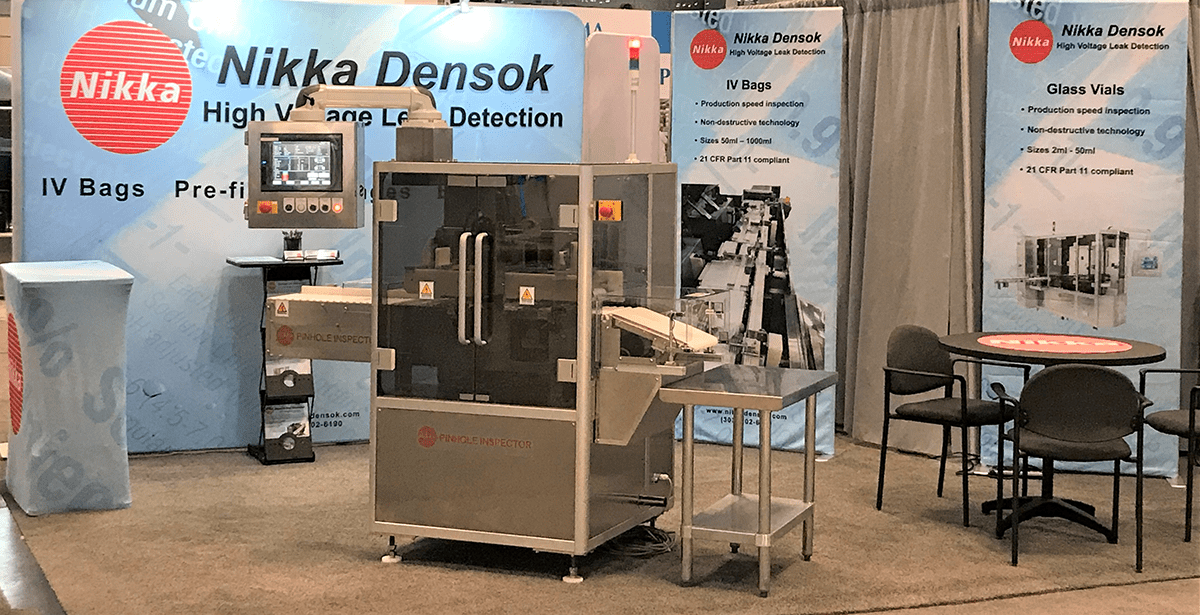

Nikka Densok USA, a subsidiary of Nikka Densok LTD in Japan, specializes in CCIT using High Voltage Leak Detection (HVLD). Nikka Densok Pinhole Inspectors are designed for non-destructive testing of a wide variety of pharmaceutical and food packages including glass, plastic and flexible packaging that contain an electrically conductive solution. The high voltage spark test method eliminates the fear of secondary contamination to the product and ensures product seal integrity by identifying small pinholes, micro cracks, and seal imperfections that cannot visually be seen.

There are a variety of methods widely used within the pharmaceutical and food industries for the detection of pinholes, cracks, and defective seals in various pharmaceutical and food packaging. These tests range from vacuum or pressure decay tests, to submerging the entire container into a dye solution under pressure and visually inspecting the container for the presence of dye, or more advanced vision systems to inspect for certain defects in the container. There is no other system in the world that will be able to detect both holes and cracks as consistent as Nikka Densok’s High Voltage Leak Detection systems.

What makes Nikka Densok HVLD unique?

Nikka Densok’s High Voltage Leak Detection (HVLD) is the most reliable, repeatable, and productive inspection method having the following advantages:

- Detectability of ≥5 micron sized holes

- Detectability of cracks

- 100% Non-destructive

- No secondary contamination to the product

- 100% inspection possible